Pressure relief devices are essential components in any system where pressurized gases or liquids are stored, transferred, or utilized—whether in industrial, commercial, or even specialized recreational settings. Their primary role is to act as automatic safety mechanisms, designed to prevent equipment failure by venting excess pressure when it exceeds a safe, predetermined threshold. This function is critical for safeguarding not only the integrity of equipment such as boilers, vessels, pipelines, and compressed gas cylinders, but also for protecting personnel and valuable assets from the potentially catastrophic consequences of overpressure situations, including explosions, leaks, and structural damage. The range of pressure relief devices encompasses several types, each tailored to specific operational needs: spring-loaded valves that open gradually or suddenly, rupture discs engineered to burst under critical conditions, and fusible plugs that provide temperature-sensitive protection by melting at elevated heat levels. These devices are integral to the smooth operation of systems found in industries like chemical processing, power generation, and even in the maintenance of hydraulic systems within vehicles and heavy equipment. The winter months, especially December, can bring unique challenges—cold temperatures can cause pressure fluctuations in stored gases, making it even more important to ensure that your pressure relief devices are properly rated and maintained for seasonal changes.

When considering the purchase of a pressure relief device, it is crucial to evaluate both the technical specifications and the specific application environment. Factors such as the type of fluid (liquid, gas, or steam), operating pressure range, temperature conditions, and the required response time all play a role in selecting the right device for the job. For instance, pressure relief valves (PRVs) are particularly suited for liquid service, opening gradually as pressure builds, while safety valves (PSVs) are engineered to open rapidly and fully for compressible fluids like gas or steam. In some cases, safety-relief valves that combine the features of both may be the optimal choice, especially in systems where both liquids and gases are present. Rupture discs offer a non-reclosing, single-use solution, acting as a rapid-response backup to traditional valves in emergency scenarios. For those working with compressed gas cylinders—common in fire protection, laboratories, and diving applications—fusible plugs provide an additional layer of safety by releasing contents when exposed to high heat. These devices are not only vital for industrial engineers and maintenance professionals, but they also make thoughtful gifts for anyone responsible for managing pressurized systems, such as facility managers, mechanics, or even avid hobbyists who work with pneumatic tools or home brewing setups. The peace of mind that comes from knowing your equipment is protected by a reliable pressure relief mechanism is truly invaluable, especially during the colder months when pressure dynamics can shift unexpectedly.

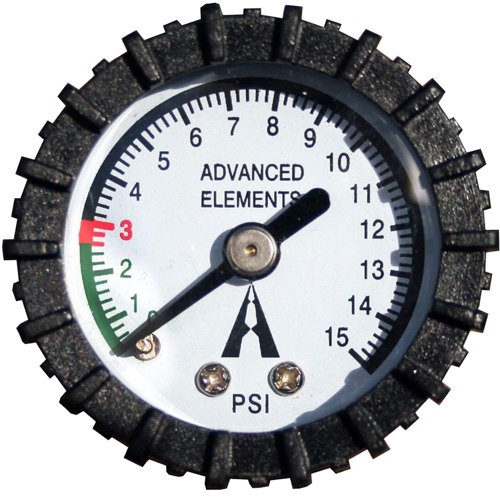

Proper integration of pressure relief devices into your system is only one aspect of comprehensive pressure management. Regular inspection, timely replacement of single-use components like rupture discs, and understanding the interplay between relief devices and related equipment are all part of responsible ownership. For those involved in underwater sports, diving, or any activity requiring precise control of pressurized air and gas, pairing your pressure relief setup with compatible

Inflation Devices can further enhance safety and performance. Whether you are outfitting a new system, upgrading existing infrastructure, or searching for a practical gift for a colleague or loved one, investing in quality pressure relief devices demonstrates a commitment to safety, efficiency, and long-term equipment reliability. The right device not only meets regulatory requirements but also delivers peace of mind through every season, ensuring that your operations remain uninterrupted and secure.