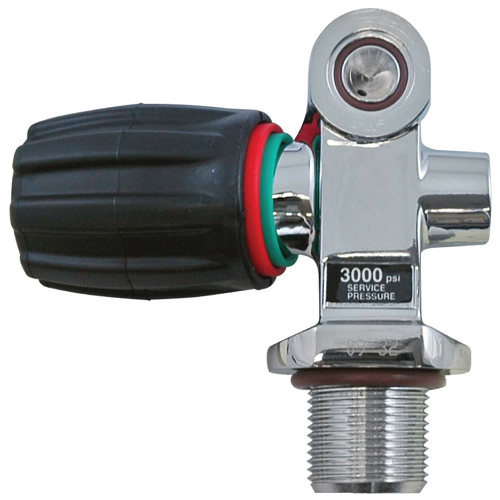

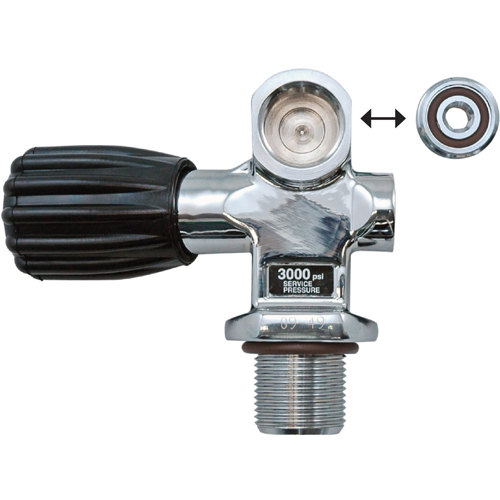

High Flow Valves

Whether you’re a seasoned technician, an avid cyclist, or someone working within specialized industries that rely on precise and efficient air or fluid transfer, high flow valves represent a critical upgrade over standard valve systems. These components are engineered to maximize flow rates, often through larger or optimized orifices and innovative internal pathways, making them indispensable wherever speed and reliability are paramount. In the context of tubeless bicycle tire setups, for example, high flow valves make the sometimes-daunting task of tire inflation remarkably smoother—especially when seating new tires or working in cold December temperatures when rubber is less pliable and sealant can thicken. The increased volume of air delivered by these valves helps seat beads quickly and minimizes the risk of sealant clogging, a common frustration for cyclists. Similarly, in vacuum systems or refrigeration applications, high flow valves enable rapid evacuation of air or gases, which can be the difference between a streamlined workflow and costly downtime. For technicians tasked with maintaining uptime in environments like semiconductor manufacturing or laboratories, the reliability and speed offered by high flow valves can translate directly into increased productivity and peace of mind.

High flow valves are not only a practical choice for professionals but also a thoughtful gift for enthusiasts who appreciate well-engineered gear—cyclists, mechanics, and hobbyists alike. For someone who spends weekends in the garage tuning bikes or prepping gear for the next adventure, unwrapping a set of high flow valves during the holiday season is both timely and meaningful. The difference is instantly noticeable: tire inflation becomes less of a chore, and maintenance routines are more efficient. In industrial settings, operators benefit from reduced evacuation times and improved system throughput, which can have a ripple effect on overall performance and energy efficiency. The design features that set high flow valves apart—such as hollow valve cores and compatibility with existing valve systems—mean they can be seamlessly integrated into a variety of setups, from pneumatic control systems to refrigeration units. This versatility makes them a go-to solution for a wide range of users, from those filling small bottles or foil packs with precision to those optimizing high-vacuum chambers for research or manufacturing.

When considering an upgrade to high flow valves, it’s worth taking into account the specific demands of your application. For cyclists, the compatibility with tubeless systems and resistance to sealant clogging are key factors. In industrial or laboratory contexts, the focus may shift toward evacuation speed, system uptime, and the ability to maintain precise control over airflow. Regardless of the use case, the investment in high flow technology pays off in time saved and frustrations avoided. For those looking to further enhance their setup, exploring related components such as

High Flow Ports can open up additional possibilities for customization and performance gains. Whether you’re gifting a friend, upgrading your own tools, or specifying equipment for a critical system, high flow valves deliver tangible benefits that are immediately appreciated in both everyday and demanding scenarios.